Precision manufactured separation technology & water treatment coanda screens

Coanda Gap is Gap Technology’s range of precision manufactured water treatment coanda screens, exploiting the Coanda effect in combination with the proven separation technology of our wedge wire. Coanda Screens are a self-cleaning screen with no moving parts that has been successfully used for debris and fish exclusion in a wide range of applications across the world including hydropower plant intakes, water conservation schemes and irrigation programs.

Coanda Screen Technology

Coanda Screens are positioned on the downstream face of an intake weir. An ogee shaped acceleration plate delivers the flow at the precise angle and velocity required by the separation area of the screen. The Coanda effect promotes consistent contact with the screen surface.

Wedge Wire placed at precise and consistent slot gap tolerance screens away debris and particles. The screened water flowing through the open area collects in a chamber beneath to be distributed to associated pipelines.

The specified tilt angle of the wedge wire has an additional shearing effect increasing throughput.

Precision Engineering

Coanda Screens can be produced in 304 or 316 grade stainless steel. The uniformity and precision slot gap of the screening area ensures high capacity throughputs and accurate removal of debris. Gap Technology wedge wire screens are utilised and trusted by clients in over forty countries worldwide.

Each Coanda Screen can be produced to bespoke dimensions and specifications with optional slot gap widths, wire profiles and inclinations to maximise performance.

MORE

For more information on coanda screen and passive water intake screen technology, please visit our dedicated website at:

www.coandascreens.co.uk

Key Benefits of Coanda Screens

- Increased hydro plant operating time, output and efficiency.

- Self-cleaning properties and largely maintenance free.

- Fine slot gap sizes from 0.2mm to 2mm.

- No mechanical moving parts.

- Modular construction ensures easy assembly.

- Abrasion and corrosion resistant.

- Operational performance at low temperatures without freezing.

Our coanda screens are also used and trusted in fisheries and conservation areas where there is no risk or harm caused to fish stocks.

Downloads

Associated documentation downloads for coanda screen and applications. To access all available downloads, please visit the Downloads Hub

- Coanda Screens

File Size: 539 Kb

Technical Data

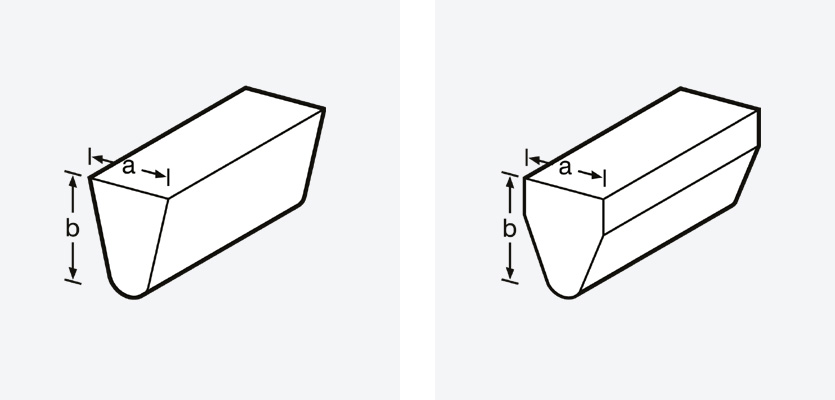

Wedge Wire Profiles and Technical Data for the Wedge Wire SB Profile, Wedge Wire SBB HS Profile, Wedge Wire GB Profile and the Wedge Wire FB Profile. The uses and possibilities of using wedge wire are pretty much endless, with the advantages to the many different types of industry sectors being overwhelming.

Coanda Screens photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding coanda screen applications in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk