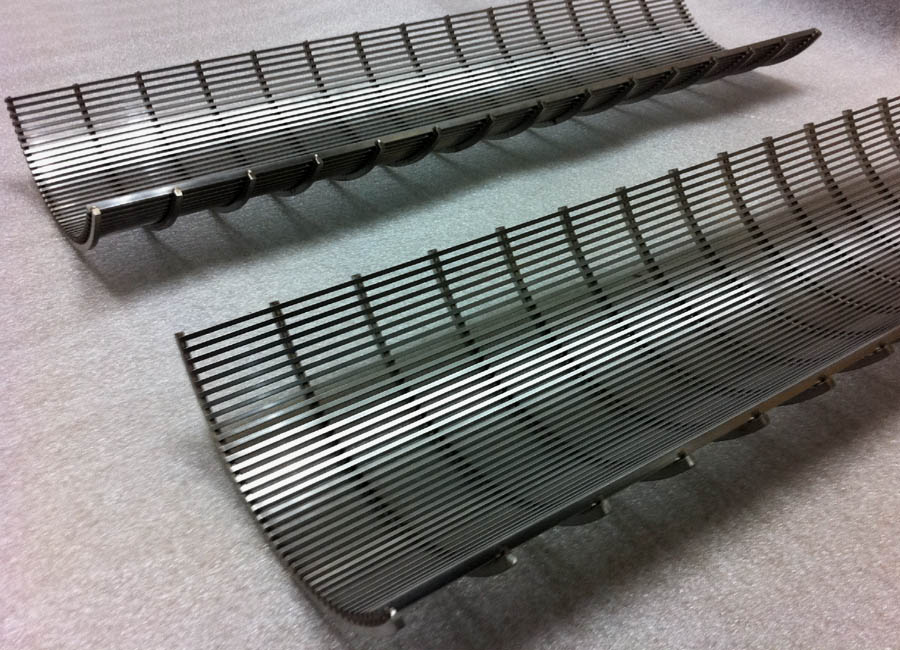

DSM Screens (Dutch State Mines) – DSM Sieve Bend Screens are ideal for sizing and dewatering applications to remove solids from liquids, or in solid/solid separation for dry feed situations. Traditional flat screens have been the standard in the industry for many years, but the DSM / curved screen has revolutionized this technology. These screens have a concave design that allows for a more efficient and effective screening process.

DSM, Curved Screen Sieve Bends

DSM / Curved screens are a vital component in the mining process, as they are used to separate and classify materials of different sizes. Adopting the cross flow wire / slot direction to break the surface tension of the flow whilst utilising the centrifugal force of a gravity fed system.

DSM Starch Screen

DSM starch screens are a type of DSM screen specifically designed for the separation and dewatering of starch in industrial processes, also known as a sieve bend screen. It is widely used in starch processing plants for the production of starches such as corn starch, potato starch, or wheat starch.

Large screening area

One of the main advantages of curved screens is their increased capacity. The curved design allows for a larger screening area, resulting in higher throughput and increased productivity. This is especially beneficial for large-scale mining operations, where efficiency and productivity are crucial.

Better drainage

Another significant advantage of curved screens is their ability to handle wet and sticky materials. Traditional flat screens often struggle with these types of materials, resulting in clogging and reduced efficiency. However, the curved design of DSM screens allows for better drainage and prevents material build-up, ensuring a smooth and continuous screening process.

Accuracy and precision

DSM screens also offer improved accuracy and precision. The concave design allows for a more natural flow of material, reducing the chances of material getting stuck or jammed. This results in a more accurate separation of materials, leading to better quality and consistency of the final product.

Applications

Curved screen sieve bends offer a wide variety of uses and applications in many industry sectors. This versatility makes them a valuable investment for companies in various sectors.

- Mining industry.

- Agriculture.

- Food Processing.

- Waste Water Treatment.

- Textile (finishing & dyeing).

Curved Screens, long lifespan.

In addition to their functional benefits, curved screens also have a longer lifespan compared to traditional flat screens. The curved design reduces stress and wear on the screen, resulting in less frequent replacements and maintenance. This not only saves time and money but also reduces the environmental impact of mining operations.

Environmental impact.

With the general focus worldwide in reducing environmental impact, the use of curved screens has contributed to this effort by reducing energy consumption and minimizing waste.

Have a question?

If you would like to ask a question or have a enquiry regarding DSM Screens / screen sieve bends in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk