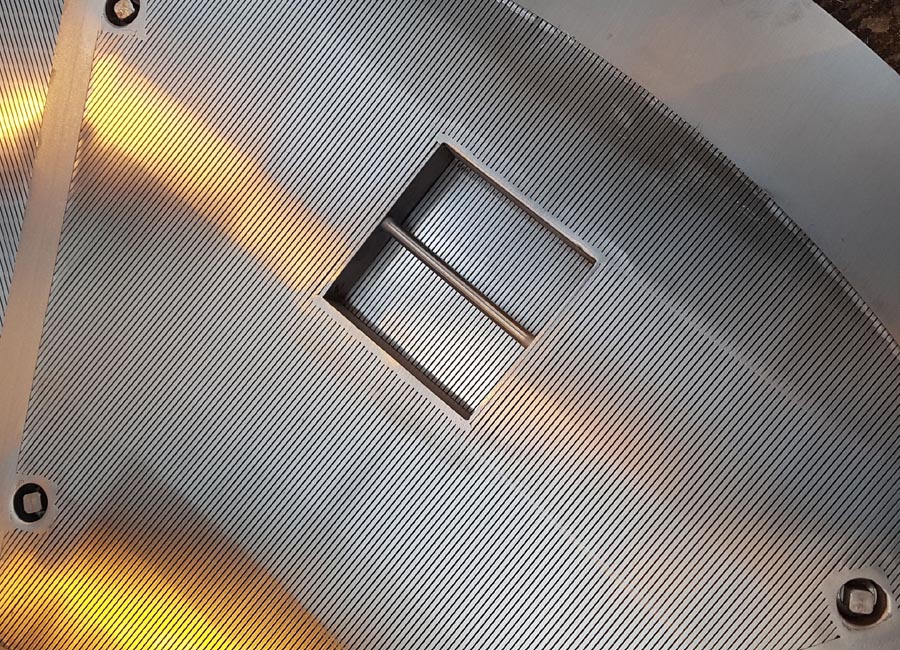

Wedge wire is ideally suited for use in the brewing industries with superior qualities over their perforated screen rivals. Using wedge wire ensures the mash tun floor screen milled area has more continuous open space and exact slots for refined filtration. Exacting filtration is crucial to keeping the husks from making it to the next boiling stage and preventing the release of bitter flavours into the beer.

Wedge Wire Mash Tun Floor Screens for optimum brewing performance

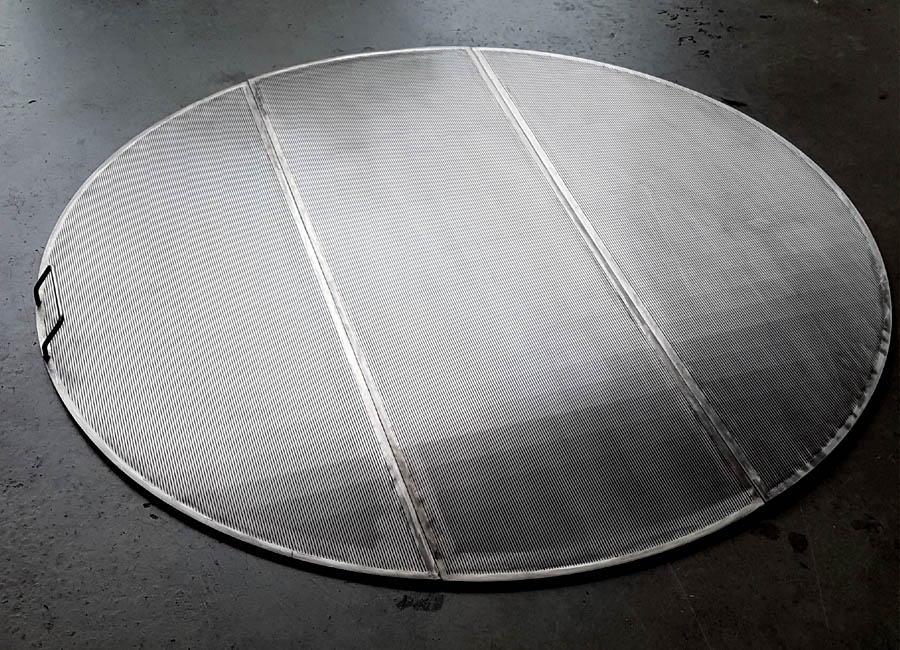

Wedge wire screen mash tun floors – superior filter screens for brewery filtration. Crafted from premium components and flawlessly engineered, our wedge wire mash tun Floors provide unmatched functionality and effectiveness. Wedge wire screen mash tun floors, in contrast to conventional perforated plates, have better filtration qualities that guarantee quick drainage and clean runoff with little husk residue. Wedge wire screens have a special design that keeps blinding and clogging at bay, enabling uninterrupted operation.

In addition to being extremely effective, our wedge wire mash tun floors are also incredibly simple to maintain. They require little maintenance because of their self-cleaning qualities, making them an affordable and hassle-free option for breweries of all sizes.

Benefits & Advantages

Gap Technology provide custom wedge wire services to cater for the needs of the global brewing industries in the form of wedge wire lauter tun screens and wedge wire mash tun screens. Their unique structure and physical characteristics allows for many advantages over perforated screen systems, including but not limited to:

- In contrast to the perforated plate, the structure is robust and has a strong compression resistance that is hard to deform.

- Large open area. The arrangement of V-shaped wires is parallel, and their opening area is superior to that of perforated plates because of the long, narrow gap in the middle.

- Fast flow rate.

- Stable gap size. As the amount of time spent using the perforated plate increases, its size will change. If the hole is not replaced, contaminants will seep into the pure wort, significantly altering the flavour of the beer. This issue is avoided with a V-wire structure.

- Not easy to block, easy to clean. Long-term use of the perforated plate will cause the hole to become blocked, which will lower flow and raise pressure drop. With its V-shaped wire structure, impurity and wire come into contact at just two places, making it difficult to block and simple to clean, giving it a longer service life.

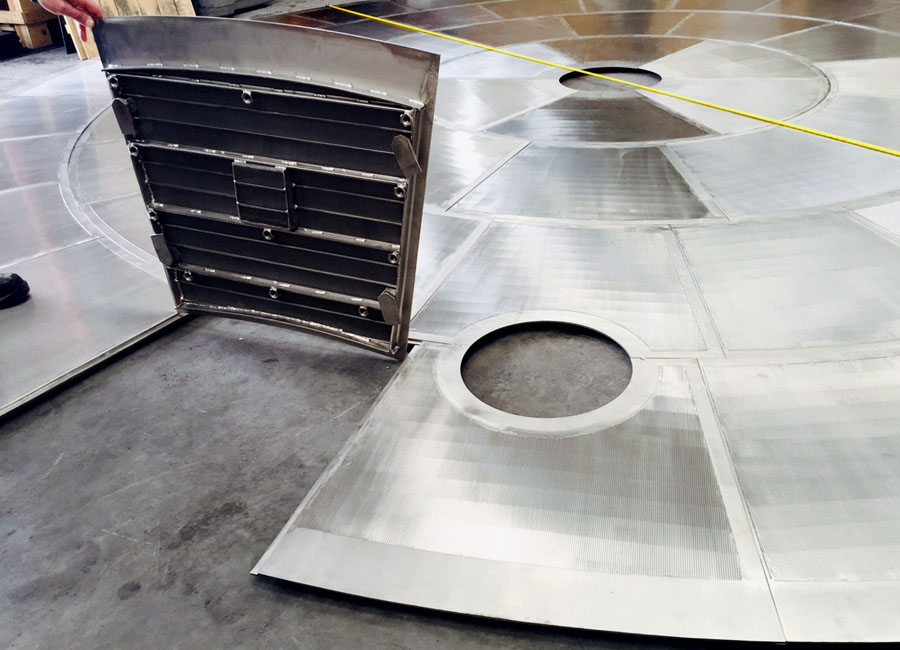

Mash / Lauter tun & Hop back false bottom screens

The longitudinal support rods and the shaped profile wire make up the false bottom sieve plate of a wedge wire beer brewing screen, mash/lauter tun screen. The V-shaped section plane can ensure that the water is unobstructed at each intersection point by avoiding blockages.

Bespoke Solutions

Whether you need circular or square floors, large or small sections for ease of cleaning, Gap Technology have the expertise to deliver wedge wire screen mash tun Floors that perfectly integrate with your brewing setup.

Contact us today for full details and enquiries

Have a question?

If you would like to ask a question or have a enquiry regarding wedge wire mash tun floor screens Lauter tun floor screens in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk