Wedge wire screens are an essential component in many industrial processes, providing efficient filtration and separation solutions. Among the various profiles many types will stand out for their durability, versatility, and high performance. In this article, we will explore the features and benefits of wedge wire screens, and why they are a popular choice for many industrial applications.

Welded Wedge Wire Screens and Panels

Welded wedge wire screens are made from V-shaped wires that are welded onto support rods, creating a continuous and uniform slot gap. This design allows for the passage of liquid or gas while retaining solids or particles, making it ideal for filtration and separation applications. This versatility also extends to the material used for the screens, with options such as stainless steel, carbon steel, and other specialist alloys available to meet specific needs.

Our range of Wedge Wire head widths varying from 0.6mm to 7.0mm with profile depths ranging from 1.30mm to 10.0mm and a slot gap range from 0.050mm (50 micron) up to 20mm will service all requirements. Careful selection from this extensive range will achieve the parameters where either a fine gauge wire will realise maximum open area or heavy duty profile will provide longevity in abrasive applications.

Another advantage of our welded wedge wire is the high open area. The continuous wires create larger openings, allowing for a higher flow rate and reducing the risk of clogging. This feature is particularly beneficial in industries where a high volume of material needs to be processed, as it ensures a more efficient and uninterrupted operation.

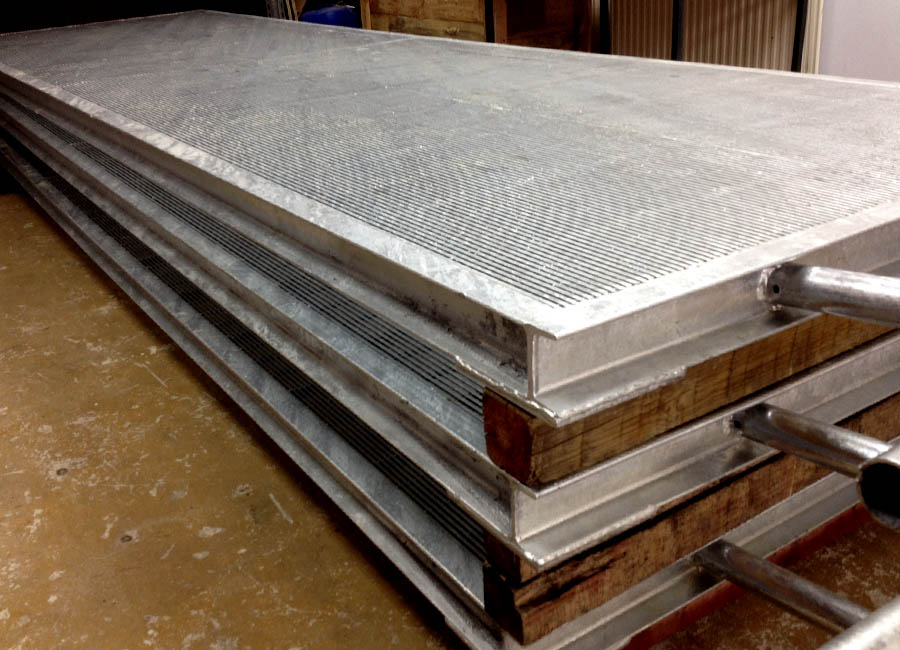

Flat panels of wedge wire screens

Flat panels of wedge wire screens are manufactured by welding special profiled working wires to support wires at an angle of 90 degrees. A precise slot is received by means of applying modern welding technology between working wires and support wires. The result is a rigid screen construction with the capability of withstanding heavy loads.

Cylindrical wedge wire screens

Cylindrical wedge wire screens are received by simultaneously winding a spiral of profiled working wire and welding them to support wires, which are arranged along the axis of the cylindrical construction. This technology allows to provide welded profile wire screens for applications where high precision of the screen together with high strength is required.

Thanks to the newest welding technology we can provide:

- optional distance between support wires.

- very precise and repeatable slot.

- screens in accordance to special requests of our clients.

Flat sieves

Flat sieves are flat panels of welded profile wire, fixed to a frame and adapted to assembly. Depending on the kind of application, flat sieves can be divided into:

- Sieves working in dynamic systems.

- Sieves working in static systems

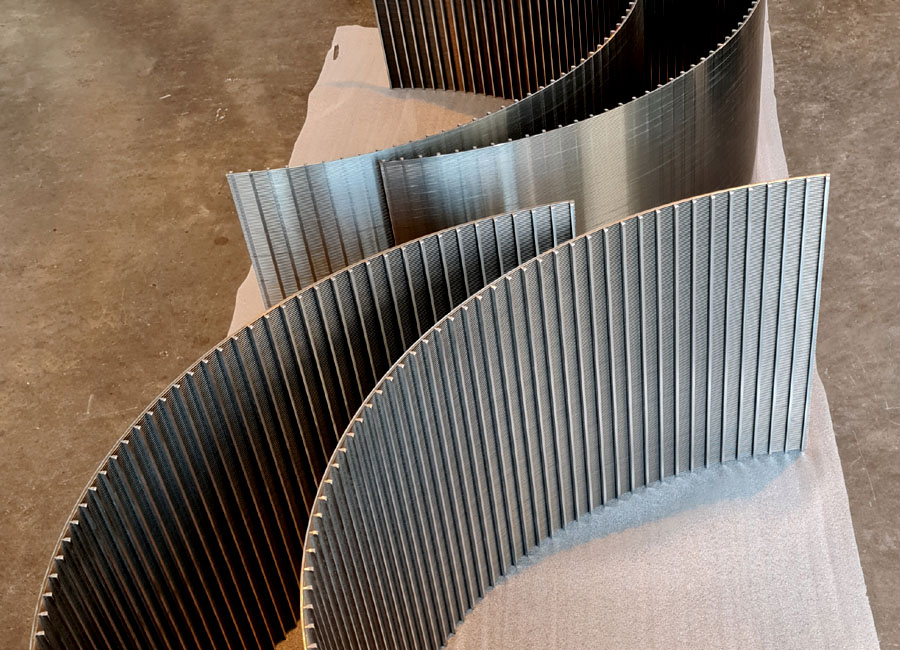

Arch / Curved sieves

Arch / Curved sieves are mainly used for dewatering and separation of solid particles from liquids. Depending on the application character, they can be divided into arch sieves with gravitational loading or arch sieves with pressured loading.

The application of arch sieve provides:

- uniform flow onto the sieve (usage of the whole

sieve surface). - high speed of flow onto the sieve.

- increased classification effectiveness and efficiency (due to the possibility of applying the working wire at a defined angle relative to support wire).

Looped wedge wire screens

Looped wedge wire screen panels are ideally suited for vibrating applications where the v shaped wires are initially formed and pressed in a dye, then threaded onto the 7.9mm diameter support rods, riveted or threaded at the ends creating a non welded screen form.

Product options

Our bespoke Wedge Wire product is designed and manufactured to separate, classify, distribute, retain and filter in a multitude of industrial processes, bringing mechanical strength and durability to its many applications.

- Wedge Wire Static Screen Panels.

- Vibrating Wedge Wire Panels.

- Fine & Coarse Screen Filters.

- Circular Filters.

- Filters, Fitments and Frames.

- Rotary Trommel Screens.

- Curved Screens.

- Cylindrical Filters.

- Filter Tubes and Cartridges.

- Centrifugal Filters.

- Coanda Screens.

Easy installation & maintenance.

Welded Wedge wire screens are easy to install and maintain, making them a preferred choice for many industries. The screens can be easily cleaned and reused, reducing downtime and maintenance costs. Additionally, their robust construction and resistance to corrosion make them suitable for use in both indoor and outdoor environments.

Efficiency, versatility & durability.

In conclusion, wedge wire screens are a highly efficient and versatile solution for filtration and separation needs. Their durable and customizable design, along with their high strength, accuracy, and open area, make them a popular choice for various industries. With their ability to withstand harsh environments and provide consistent and precise separation, welded wedge wire screens are an essential component in many industrial processes.

Have a question?

If you would like to ask a question or have a enquiry regarding Wedge Wire Screens in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk