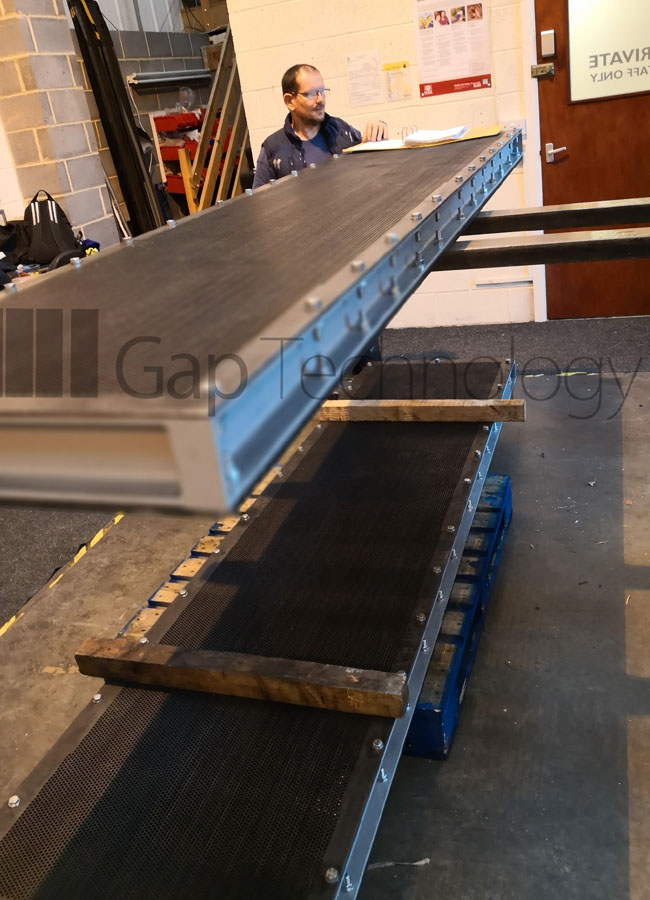

Metal Perforated Screens & Sieves

Perforated Screens are produced from metal plates or metal sheet rolls which are perforated on high-pressure punch presses by means of special tools. The type of tool is selected according to the required perforation method. The holes are on the perforated screens are usually laser cut in case of metal plates thicker than 10mm.

Application include

Sugar processing, germination and kiln floors (malting panels), recycling and waste water.

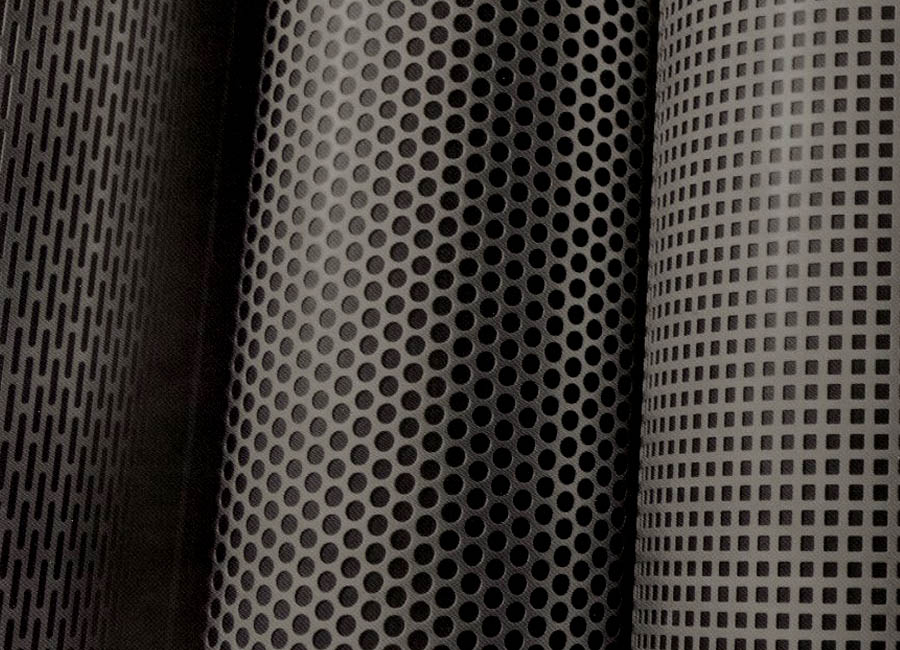

Perforated Screen patterns & options

Gap Technology produce an extensive range of stainless steel and mild steel perforated screens finished products for a variety of applications across a broad spectrum of industrial sectors. Contact Gap Technology for support and enquiries.

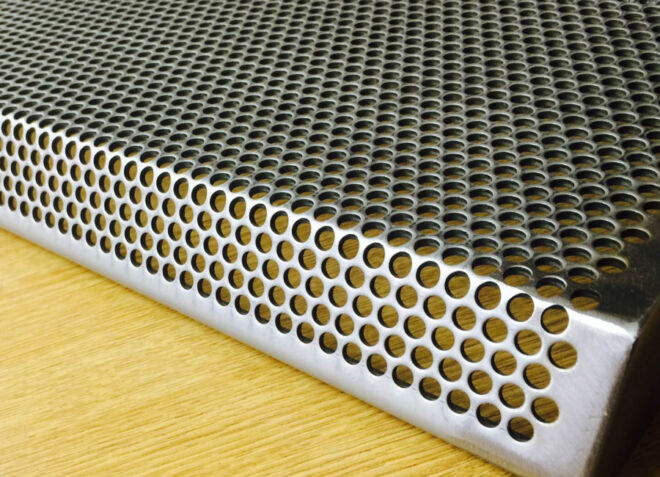

Round Hole

Round Hole perforated screens and sieves applications include:

Building Industry • Recycling Industry (bulk material sorting) • Agriculture Industry (sorting and grading of seeds) • Architectural Applications – Facades and Cladding etc.

Square Hole

Square Hole perforations applications include:

Balconies and Balustrades • Safety Guards for the Building Industry • IT Industry – Ventilation covers for computer and server chassis.

Slot Hole

Slot Hole perforated screens and sieves applications include:

Malting, Breweries and Wineries • Farming Machinery • Recycling Industry • Food Processing Industry.

Hexagonal

Hexagonal perforation holes applications include:

Automotive Industry – Car Mesh Grilles • Information Technology Industry • Architectural Applications.

Bridge Hole

Bridge Hole perforated screens and sieves applications include:

Agricultural Industry (grain drying) • Geological Industry (drilling, shaft sinking).

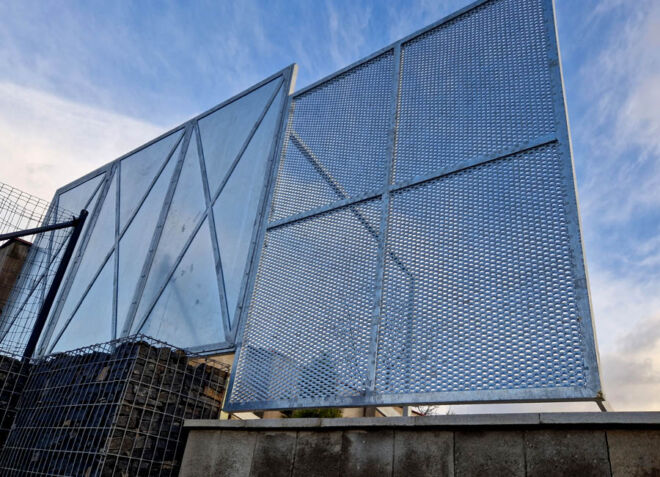

Perforated Screens photo gallery

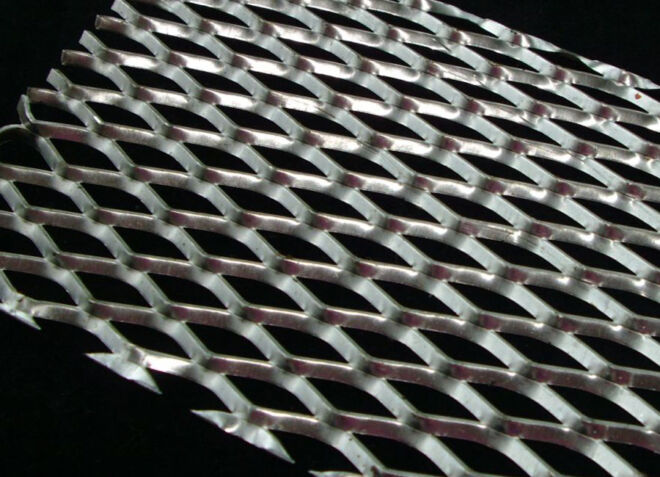

Expanded Metal Sheets

Production

Expanded Metal Sheets are produced in the following way – the row of mesh is cut into a roll or sheet and then the material is expanded. This procedure is repeated until the product gets its final shape.

Producing expanded metal sheets in this way gives a slightly crimped surface as the material, whilst being drawn, turns slightly vertically, that is why subsequently it is possible to press expanded metal in order to get an even surface.

Applications include

- Decorative and Safety Covers.

- Architectural Elements.

- Bulkhead, Fillers, Grids and Reinforcers.

- Staircases.

- Grates.

- Acoustical Insulation.

Range Availability

Gap Technology have a comprehensive selection of materials and patterns of Expanded Metal Sheets. in standard specifications, or alternatively, we can produce bespoke Expanded Metal Sheets products and Perforated Screens to cater for individual requirements.

The wide range of products and industries catered for ensures we remain focused on our customers needs.

Photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding perforated screens and sieves in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk