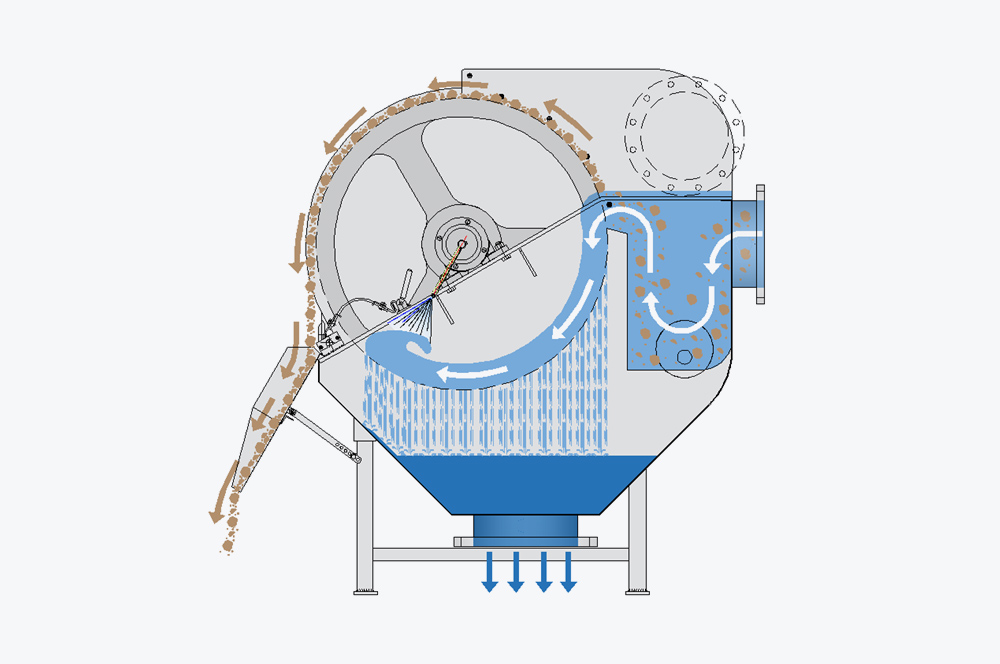

External Rotary Screens reduced flow velocity ensures uniform & controlled distribution of liquids & suspended solids

Introduction

Suspended solids by rotation are efficiently removed by a spring loaded doctor blade, whilst the screened liquid passes through the cylinder and performs a systematic backwash of the screen opening on its exit to the outlet chamber. Flow is presented to a circumferentially wound external wedge wire drum, with dewatering taking place immediately on contact with the carefully selected Slot Gap screen cylinder.

An Integral Wash Facility is provided to intermittently flush the screen, providing maximum open area at all times, affording high capacity throughputs with the ability to separate fine and hostile particles.

Wedge Wire profiles and technical data.

Features & Benefits

External Rotary Drum Screens operate with a pumped or gravity feed entering the inlet launder designed to reduce the flow velocity and ensure a uniform and controlled distribution of liquids and suspended solids.

- Designed to reduce flow velocity.

- Controlled distribution of liquids & suspended solids.

- Widths (mm): 300 – 3000.

- Diameters (mm): 410mm – 920mm.

- Separate fine and hostile particles.

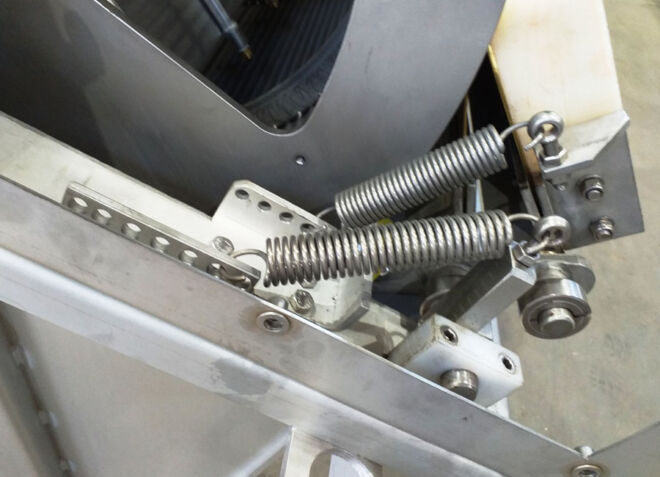

- Self cleaning, mechanical spring loaded scraper.

On-site Demonstrations

External Rotary Drum Screens on-site demonstration facilities are available along with the entire range of our Waste Water Screening Machines, each with interchangeable screen elements to determine the ideal separation of your materials.

Gap Technology Limited also provide structural steel work including platforms, handrailing and access ladders with a bespoke design, commissioning and installation service.

Interested in an on-site demonstration?

Contact Gap Technology

Technical Information & Specifications

| Types | Modular |

| Media: Liquids | Grey Water, Industrial Effluents, Process Water, Sewage & Storm Water |

| Media: Solids | TSS Reduction, Industrial and Municipal Process Screenings |

| Screen Types | Rotating screens, Coarse and Fine Separation |

| Materials | Stainless Steel, Stainless Steel (304) and Stainless Steel (316) |

| Features | Self cleaning, Mechanical Spring Loaded Scraper |

| Maximum aperture size (mm) | 2.5 |

| Minimum aperture size | 0.25 |

ERS 405 FLOW CAPABILITIES (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| TYPE | SLOT GAP s (mm) | ||||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | 2.50 | ||

| ERS 405 x 500 | 30 | 52 | 70 | 75 | 100 | 122 | |

| ERS 405 x 750 | 45 | 82 | 103 | 118 | 160 | 195 | |

| ERS 405 x 1000 | 62 | 103 | 130 | 155 | 196 | 212 | |

ERS 640 FLOW CAPABILITIES (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| TYPE | SLOT GAP s (mm) | ||||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | 2.50 | ||

| ERS 640 x 500 | 25 | 55 | 75 | 100 | 125 | 130 | |

| ERS 640 x 750 | 40 | 90 | 125 | 130 | |||

| ERS 640 x 1000 | 54 | 120 | 130 | ||||

| ERS 640 x 1250 | 68 | 130 | |||||

| ERS 640 x 1500 | 81 | 130 | |||||

| ERS 640 x 2000 | 108 | ||||||

ERS 916 FLOW CAPABILITIES (m3/hour)

Reference capacities for water with contamination of 200mg/l at given slot. Figures are based on average throughputs and conditions. For specific applications please contact technical sales

| TYPE | SLOT GAP s (mm) | ||||

| 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | |

| ERS 916 x 1500 | 170 | 320 | 450 | 530 | 700 |

| ERS 916 x 2000 | 228 | 380 | 570 | 680 | 900 |

| ERS 916 x 2500 | 310 | 540 | 750 | 900 | 1200 |

| ERS 916 x 3000 | 350 | 620 | 870 | 1040 | 1390 |

External Rotary Screens Photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding waste water screening machines in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

[email protected]