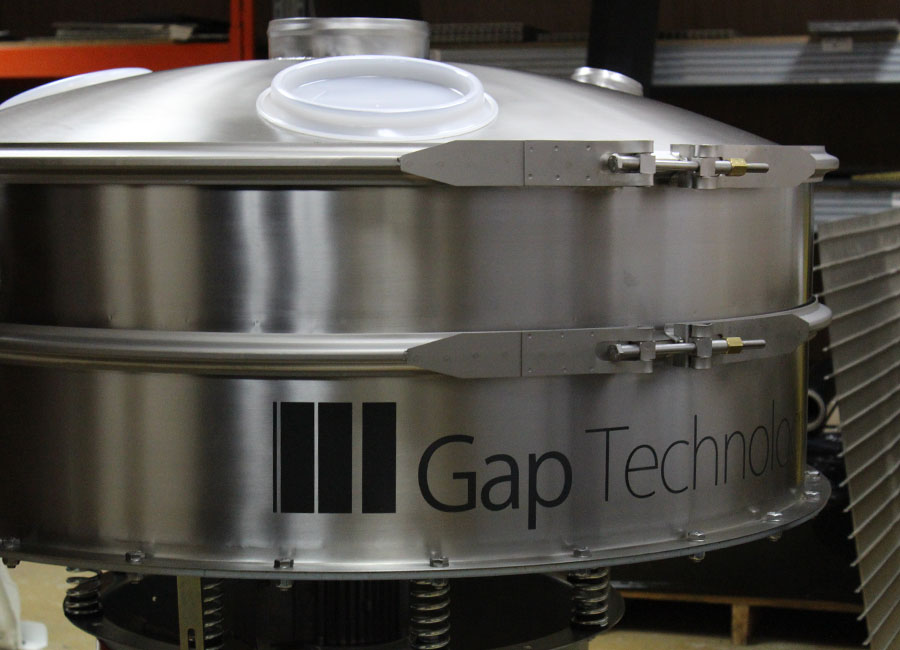

V Range Vibrating screens & separators designed to perform fine solid & liquid separation

Introduction

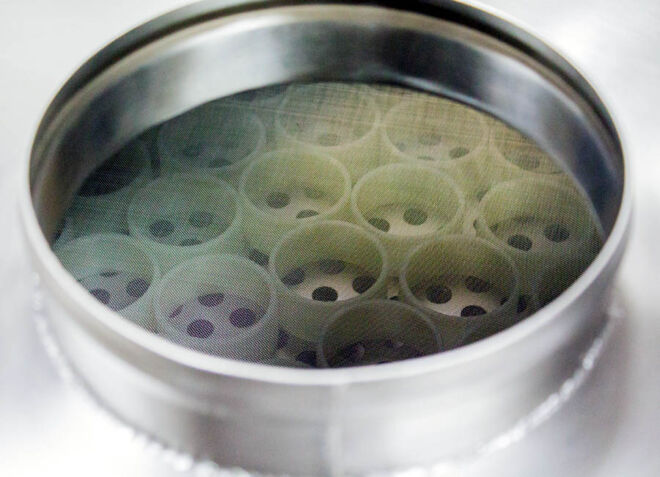

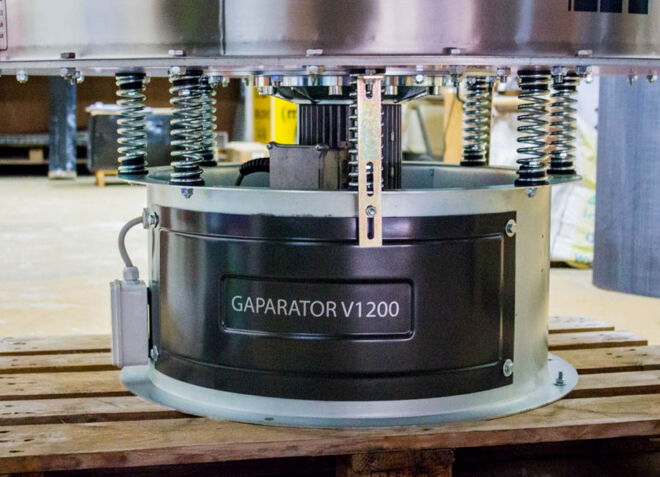

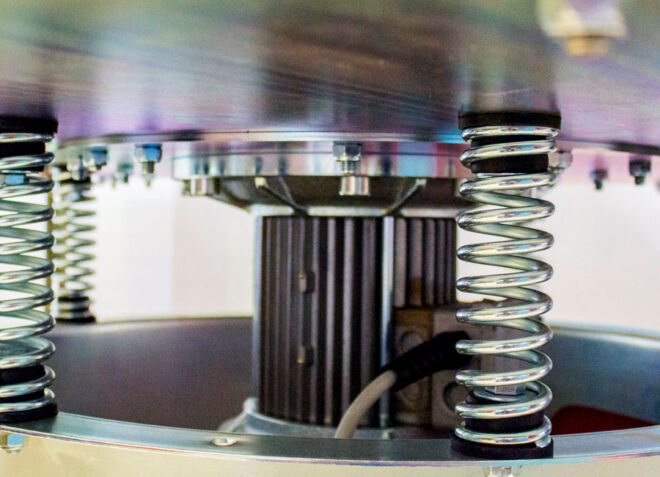

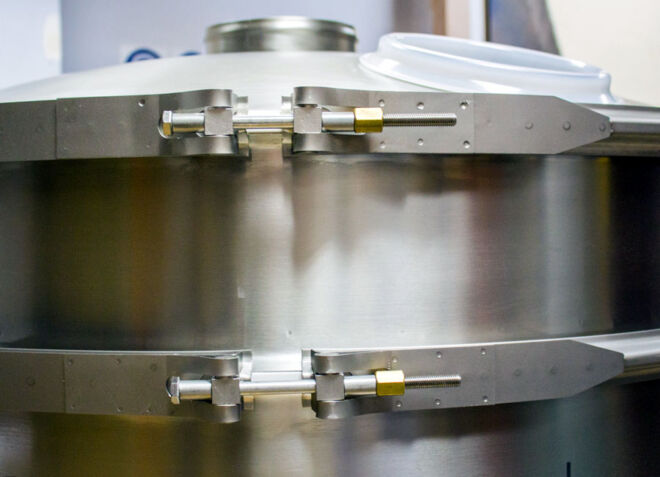

Vibrating Screens can operate up to a maximum temperature of 200 degrees C for hot liquid separation or filtration. All Vibrating Screens normally feature a high top processing deck, ensuring that all materials pumped onto the process deck are retained within the process area to minimise any splashing of product (if necessary a top cover can be fitted to the vibrating screens unit). Vibrating Screens are supplied in a fixed base form as 915mm, 1200mm, 1500mm or 2000mm diameters with 1-2 process decks and are normally fitted with balls or sliders as a mesh de-blinding aid to increase screening efficiency.

Applications Include:

- Refining of fruit juices.

- Waste water recovery in industrial laundries.

- Cooking oil filtration.

- Waste oil recovery.

- Plastics recycling.

- Initial screening of pressed apple juice to remove oversizes.

Features & Benefits

V Range Vibrating Screens are vibrating screening separators specifically designed to operate for fine solid and liquid separation applications. This can be from De-Watering, Slurry Processing, Waste Oil Filtration and Waste Water Processing, or any application that requires some form of size classification.

- Designed for continuous use.

- De-Watering.

- Slurry Processing.

- Waste Oil Filtration.

- Waste Water Processing.

- Screens tailored to suit individual applications.

- Accessories to maximise screening efficiency.

- Supplied in a fixed base form as 915mm, 1200mm, 1500mm or 2000mm diameters. Contact Gap Technology for support and enquiries.

On-site Demonstrations

V Range Vibrating Screens / Screening Separators on-site demonstration facilities are available along with the entire range of our Waste Water Screening Machines, each with interchangeable screen elements to determine the ideal separation of your materials.

Gap Technology Limited also provide structural steel work including platforms, handrailing and access ladders with a bespoke design, commissioning and installation service.

Interested in an on-site demonstration?

Contact Gap Technology

Gaparator V Range

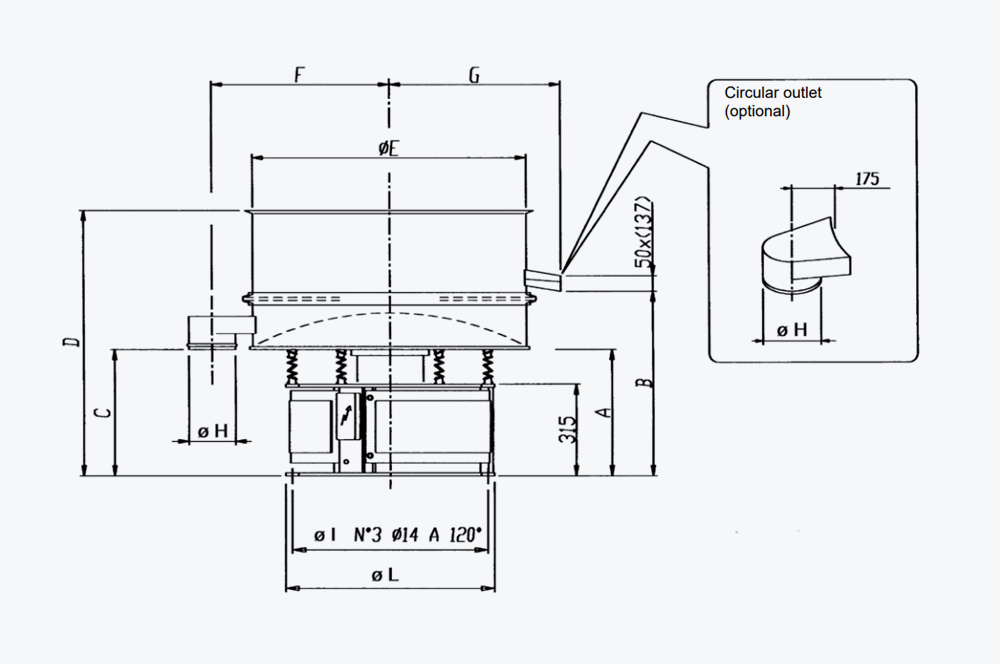

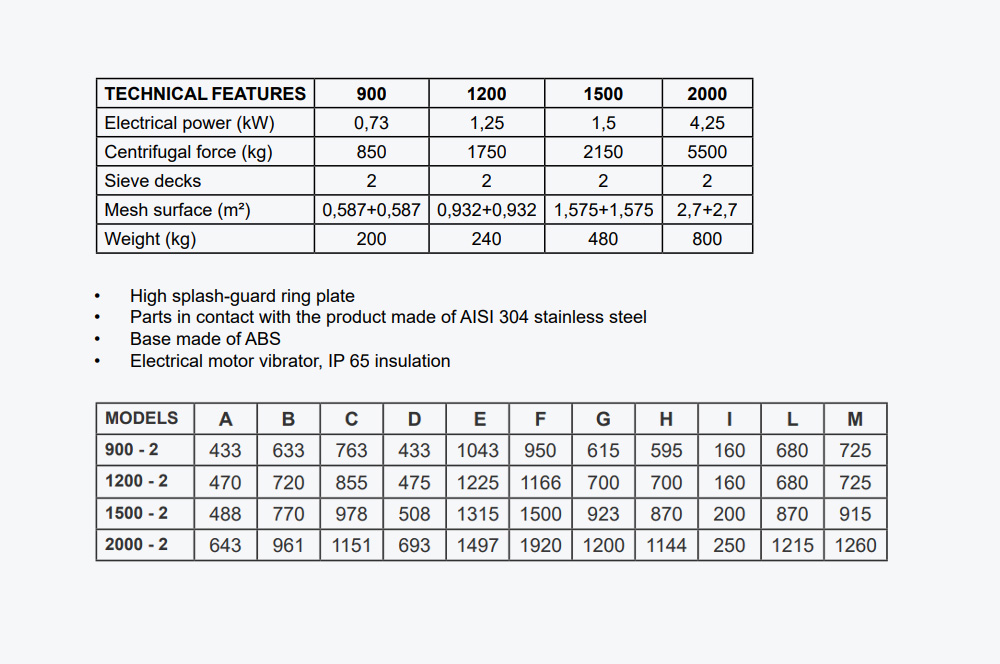

Technical Drawings & Data

As with all our Gaparator waste water screening machines, these Vibrating Screens can be tailored to suit individual applications with additional accessories to maximise screening efficiency and product throughput. All our Vibrating Screens are manufactured from 304L Stainless Steel as standard with 316L Stainless Steel contact parts available as an optional extra. Contact Gap Technology for support and enquiries.

Gaparator V-Range 1

Technical & Construction Features, Advantages and Applications

Download PDF / 647Kb

Gaparator V-Range 2

Technical & Construction Features, Advantages and Applications

Download PDF / 647Kb

Photo gallery

Have a question?

If you would like to ask a question or have a enquiry regarding waste water screening machines in general, please contact us. A member of our team is on hand and ready to help.

– – – – – – – – – – –

Telephone: +44 (0) 1777 710 710

[email protected]