Macallan Distillery and Visitors Centre image gallery

Design, manufacture and install of Architectural Walkways and Process Tables at Macallan Distillery and Visitors Centre

With the Gap group of companies already having completed two successful projects for the new ‘The Macallan’ distillery, Gap architecture were awarded the contract to design, manufacture and install the architectural walkways and process tables in the state-of-the-art working visitors centre.

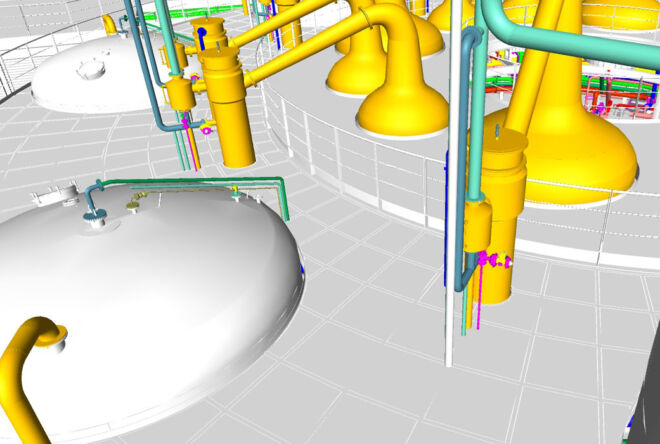

Working closely with the London based architect, Gap Architecture were provided with a design intent for circa 3000 number bespoke stainless-steel flooring grille panels to form a suspended walkway around each vessel, still, intricate pipework, lighting columns and stairways.

The parameters of the grille panels were to cover a 5mm wide surface profile with an 11mm uniform gap, each had underside supports to facilitate an open feel from above whilst ensuring a minimum of 5kn per square metre pedestrian load criteria.

The scale of the project comprised of 4 x 30 metre diameter process tables flooring encompass the mash house and still houses 1,2 and 3, with link bridges and access stairways strategically located for maintenance and tour groups.

Considering the global brand of ‘The Macallan’ in the world of single malt whiskeys, each and every aspect of the state-of-the-art distillery and visitors centre utilized only the highest engineered materials and world leading manufacturing processes.

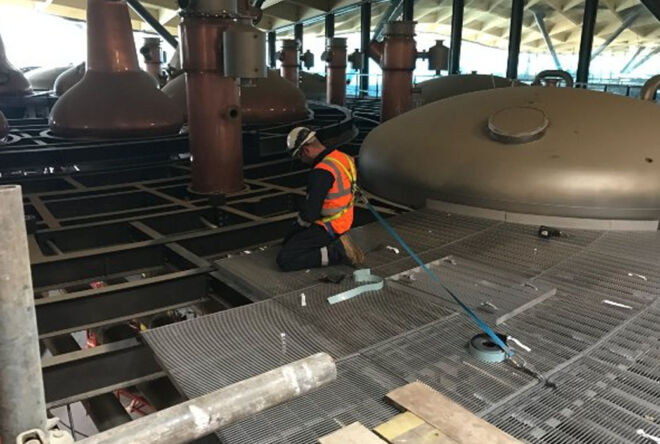

The self-cleaning properties and high aesthetic finish of the Gap Architecture fitted grilles were to be manufactured and installed with a uniform wire profile and slot gap dimension, with the underside supports all running in-line with each panel, similarly :- a 5mm shadow gap was required between each adjacent panel throughout the installation. All conforming to stringent health and safety measure and working over 15m high within the build site.

With Gap having designed a discreet fixing method and form arrangement, it enables the panels to be keyed and fastened from above. Gaps installation also included 4 rubber cushioning strips and pads to alleviate vibration.

To allow for all the distillery process pipework, Gap had to intracity waterjet cut the wedge wire grilles in strategic locations with the addition of bespoke stainless-steel cover plates welded during installation.

The wedge wire flooring significantly complements the impressive lighting effects and showcases both aspects to their full potential.

MORE

Contact Gap Technology

for more information, support and enquiries.

Gap Technology Limited

Head Office & Works

Ava House, 1 Hill Court

Aurillac Way

Retford

Nottinghamshire

DN22 7PX

Telephone: +44 (0) 1777 710 710

info@gaptechnology.co.uk